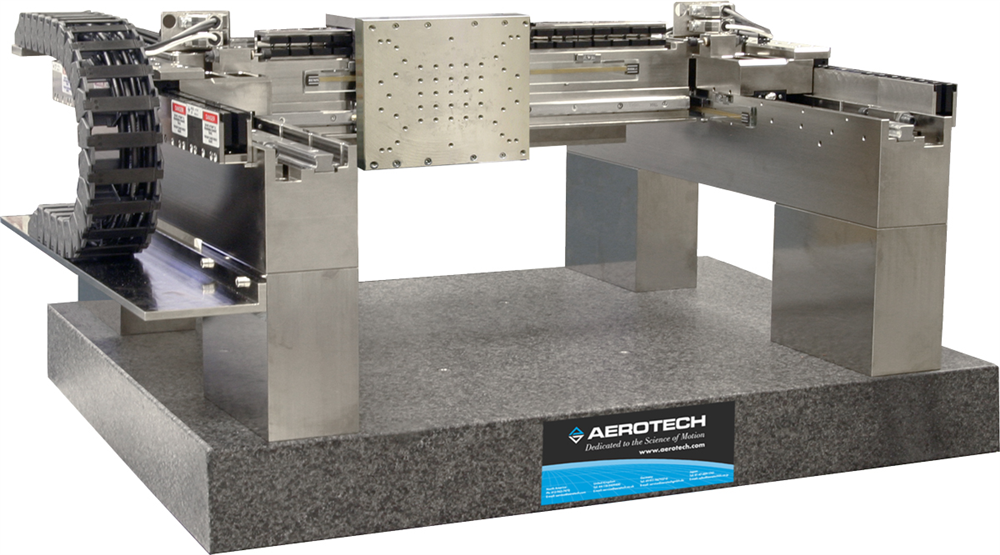

Aerotech AGS1500 Gantry System

The AGS1500 series of Cartesian gantry systems is designed for ultra-precision, high-dynamic contouring, providing outstanding performance and versatility in a wide range of automation platforms. The planar design minimizes dynamic pitch errors at the work-point.

Features:

- Optimised design for precise contouring in a compact footprint

- Velocity to 3m/s and acceleration to 5g

- High power brushless linear servomotors for smooth motion

- Travels up to 500mm x 500mm

- Optional electroless nickel for ESD protection

- Customisable Z and theta axes for flexible configurations

- Noncontact linear encoders

- Configurable cable management system allows for integration of fiber lasers, cameras, air lines, etc. for multiple applications

AGS1500 systems can be found in production plants around the world, in applications including precision micromachining, stencil cutting, fuel cell manufacturing, solder-ball placement, printed electronics, high-speed pick-and-place, automated assembly, vision inspection, dispensing stations and high-accuracy inspection. The AGS1500 is based on the industry-leading AGS15000 gantry, and maintains many of the same leading-edge characteristics.

High Speed/High Acceleration

Aerotech's high-performance BLMC and BLM series brushless linear servomotors drive the AGS1500 to speeds of 3m/s and accelerations of 5g. Dual linear motors and encoders are included on the lower axis for the highest level of performance and precision. The rugged noncontact optical linear encoders offer resolutions to 1nm when coupled with Aerotech's controllers.

Rugged Design

The linear motor is a noncontact device, resulting in no backlash, wear or maintenance. The bearings are preloaded linear motion guides with wiper seals and grease fittings, and are mounted to provide optimised dynamic stiffness and load distribution.

The AGS1500 design keeps the linear motors and linear encoders to the outside of the work area. This design makes the gantry less susceptible to debris-induced damage.

Long-Lasting Cable Management System

The cable management system (CMS) is optimised and field-proven as the industry's most reliable design. Large bend radii and high-flex cables ensure that the AGS1500 provides millions of cycles of maintenance-free operation. In the unlikely event of a component failure a modular design ensures that part replacement is fast and easy.

All customer cabling and pneumatics can be routed through the system e-chain. Connectors are provided at the workpiece and at the opposite end of the e-chain, greatly simplifying final machine integration.

For further information please contact us or download the datasheet.