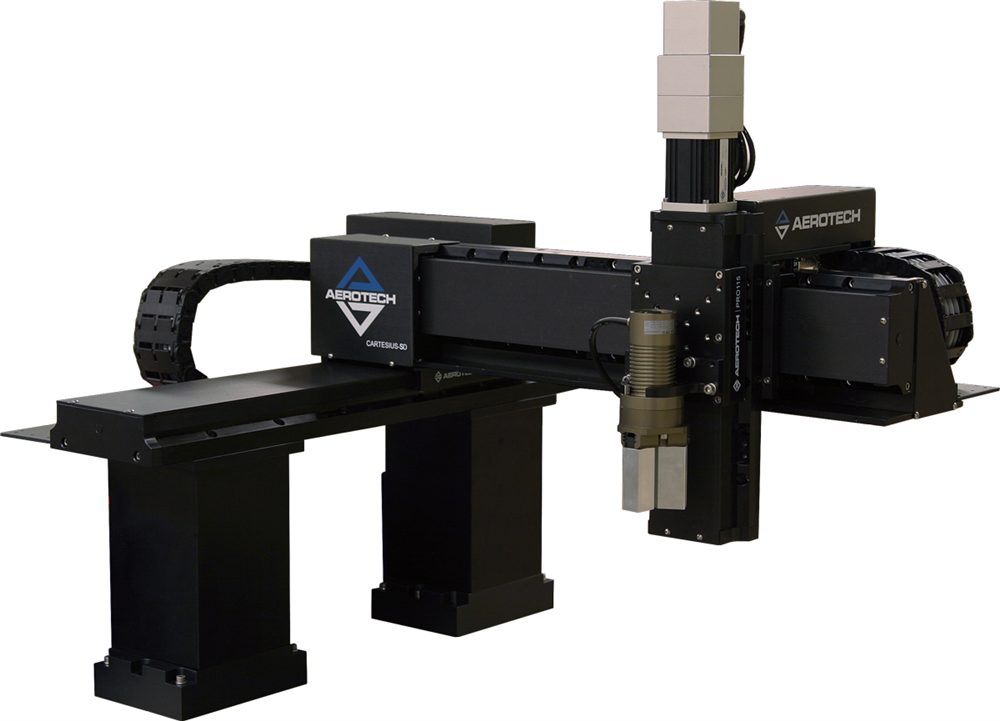

Aerotech Cartesius Cartesian Robot Gantry System

Aerotech Cartesius Cartesian Robot Gantry System

Ideal for many automation applications including pick and place

Cartesius, Aerotech's industrial strength Cartesian robot, is built on the Aerotech PRO series linear stages and is ideal for many automation applications including pick and place, assembly, test and inspection, dispensing stations and many more.

Features:

- Configurable T-style robot up to 1.0m x 0.5m x 0.3m travel

- Velocities up to 1.4m/s provide high throughput

- Integrated Cable Management System (CMS) shortens your machine build

- 3-axis load up to 25kg for demanding applications

- Customizable Z and/or theta axis for easy integration of any process equipment

- Teach mode with Aerotech controllers for fast deployment

Highly Configurable

Cartesius standard configurations include left or right handed XY, XYZ and XZ systems. Stages can be side or base mounted and the Z axis can be base or carriage mounted. An optional rotary axis can be mounted to the Z. The integrated cable management is connectorised for easy disconnect for customer cables and air lines. All stages have environmental protection, servomotors with encoders, integral limits and multiple ball-screw leads providing a wide range of speeds and resolutions. If a standard configuration does not meet the application requirements, Aerotech can design and manufacture a custom Cartesius robot.

Competitive pricing coupled with Aerotech's reputation for producing high-quality linear motion systems make Cartesius an attractive robot for medium-performance applications.

Cable Management System

Aerotech's extensive design experience with 24/7 production equipment has resulted in an optimised CMS that is field proven to be the industry's most reliable design. Large bend radii and high-flex cables ensure that the Cartesius CMS provides millions of cycles of maintenance-free operation. In the unlikely event of a component failure, the modular design ensures that part replacement is fast and easy.

Customer cabling and pneumatics can be routed through the CMS system. Connectors are provided at the workpiece and at the base, greatly simplifying final machine integration.

Rugged Construction

Cartesius is configured with Aerotech's PRO series stages: PRO115, PRO165 and PRO225. These precision ball-screw stages are driven with brushless servomotors with encoders for position feedback. The stages are designed with hard covers and side-seals for protection from debris. The robust aluminum cover is hard-coated to provide a scratch resistant surface. The side seals keep dirt and particulates out of the stage and protect the bearing surfaces and ball screw from contamination. The vertical orientation of the seals easily deflects debris away from the stage.

For further information please contact us or download the datasheet.