Bruker Hysitron PI 89 Auto Picoindenter

Bruker Hysitron PI 89 Auto Picoindenter

Automated co-localised imaging and analysis for high-throughput in-situ nanoindentation

Bruker’s PI 89 Auto brings full automation to our market-leading Hysitron PI 89 SEM PicoIndenter. The new tool facilitates correlative structure-property analysis by automatically moving the advanced Rotation and Tilt Stage (R/T stage) to the indentation position following SEM imaging and EBSD/EDS mapping.

Combining new TriboScan Auto software with this R/T stage enables the PI 89 Auto to achieve previously unattainable high-throughput testing with exceptional precision and control.

Features:

- Seamless switching between nanoindentation, standard SEM imaging, EBSD/EDS analysis;

- Co-localised acquisition of quantitative in-situ mechanical data at user-defined regions of interest from imaging and analytical mapping; and

- Increased throughput without compromising precision or accuracy.

Today’s industrial settings require increasingly fast and accurate materials characterisation. The new PI 89 Auto delivers this and the other critical capabilities necessary to revolutionise materials testing in the steel, automotive, aerospace, nuclear, and semiconductor sectors.

For further information please contact us or download the datasheet.

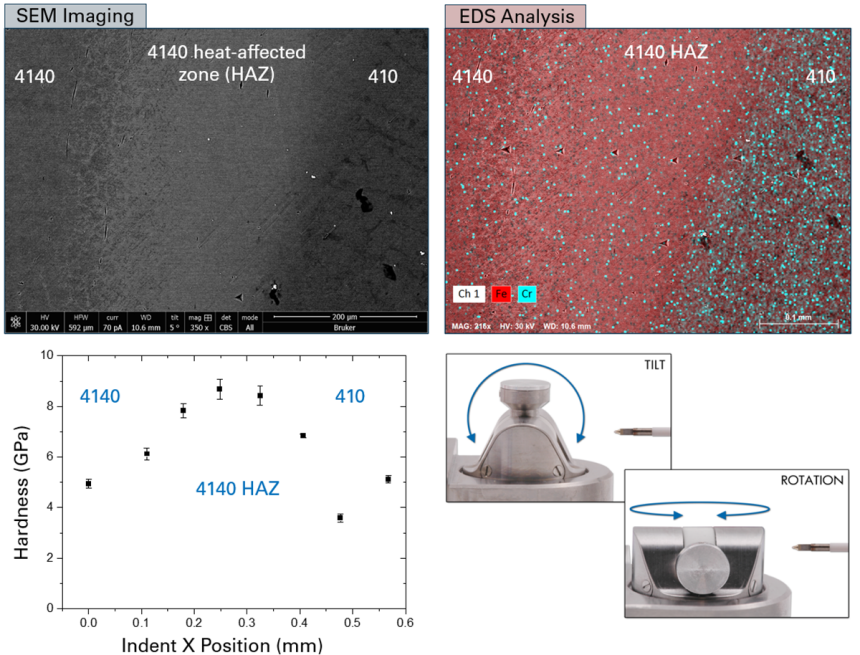

The PI 89 Auto (top) was utilised to perform SEM imaging (middle left), EDS analysis (middle right), and hardness profiling (bottom left) of a laser clad region of 410 stainless steel onto a 4140 steel substrate. Once the locations of indentation were selected on the live SEM images and the EDS mapping was captured, TriboScan Auto interface ran the tests automatically at these location and obtained mechanical properties. The SEM and EDS from a sample can be captured using the tilt function of PI 89 Auto system and EBSD mapping can be obtained using the rotation function of PI 89 Auto (bottom right).