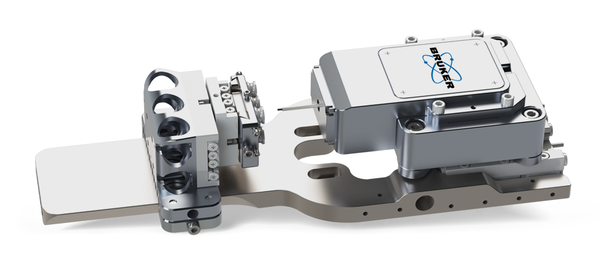

Bruker Hysitron PI89 SEM PicoIndenter

Bruker Hysitron PI89 SEM PicoIndenter

Robust, precise and modular in-situ SEM nanomechanical instrument

The Hysitron PI 89 SEM PicoIndenter leverages the advanced imaging capabilities of scanning electron microscopes (SEM, FIBSEM, PFIB), making it possible to perform quantitative nanomechanical testing while simultaneously imaging. PI 89 further advances Bruker's market-leading capacitive transducer technology, which enabled the first commercial in-situ SEM nanomechanics platforms. The new PI 89 Auto adds full automation to four techniques: EBSD, EDS, SEM imaging, and mechanical property mapping.

Techniques available on PI 89 include nanoindentation, tensile testing, pillar compression, particle compression, cantilever bending, fracture, fatigue, dynamic testing, and mechanical properties mapping.

Features:

- Proprietary interchangeable transducer technology provides extended range (10mN, 500mN, 3.5N and 150μm) in-situ nano- to micro-scale mechanical testing

- Exclusive load and displacement-controlled testing modes enable nanoindentation, compression, tension, fatigue or bending tests

- New encoded stage technology (1nm resolution) enables indentation within nanocrystalline grains

- Two rotation/tilt stage configurations enable better sample positioning for nanomechanical testing, secondary electron imaging, iin-situ FIB milling, and analytical imaging

- Futureproof modular design allows for upgardeability of in-situ testing tecniques, including 800°C heating, scratch testing, electrical characterisation, scanning probe microscopy (SPM) imaging, property mapping (XPM), and dynamic fatigue tsting

- Performech® II Advanced Control Module delivers 78kHz feedback rate and data acquisition up to 39kHz to capture transient events, such as fracture initiation

For further information please contact us or download the datasheet.